Sustainability

Certificates & Partnerschips

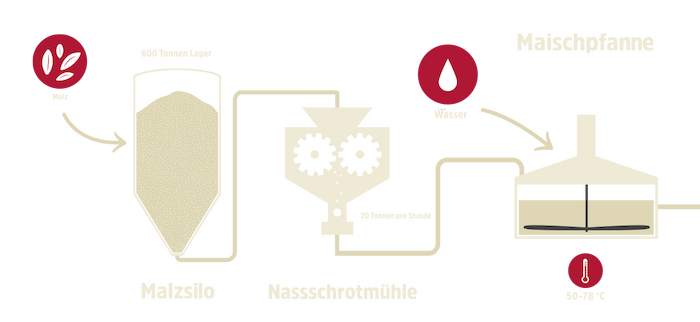

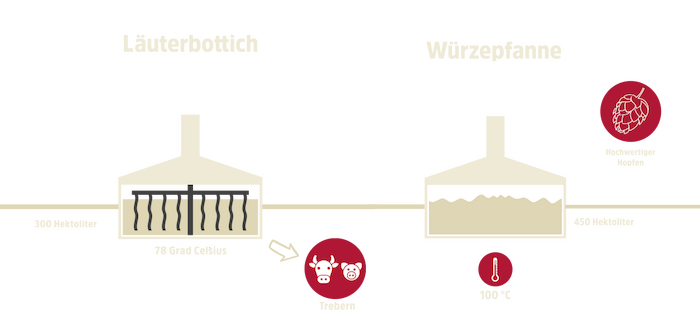

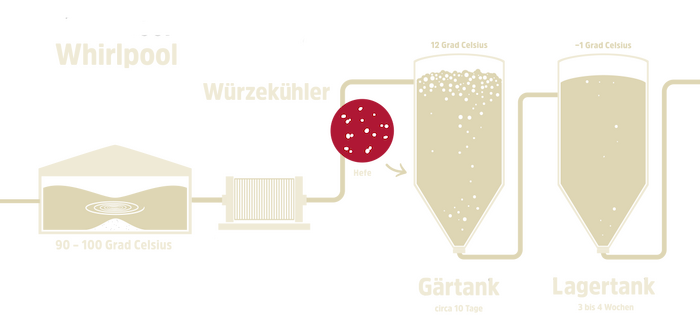

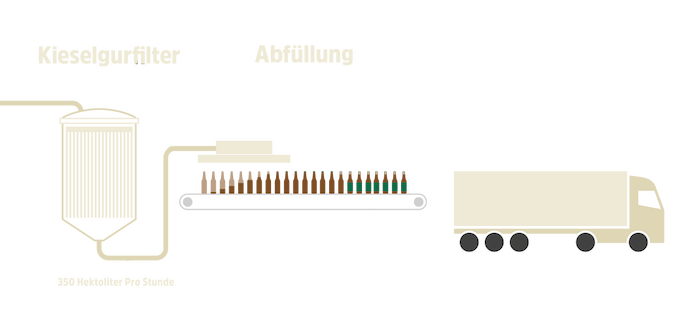

The process of beer brewing

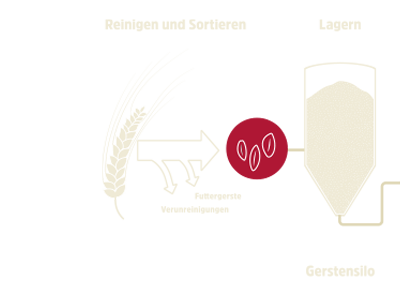

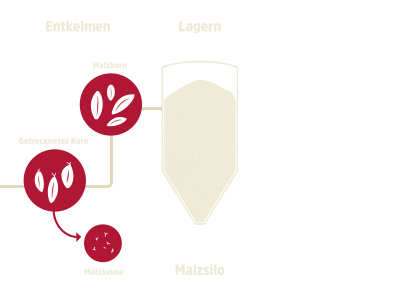

The malt production

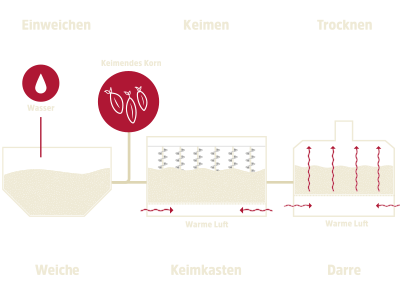

Malt is the essential ingredient in beer production and plays a crucial role in developing the taste, color and aroma of the beer. Malt production is a fascinating process that requires care, expertise and time. After the freshly harvested malting barley is delivered, it must be stored in the Austrian malthouse for around 6 weeks in order to dissipate the harvest heat and to allow the grain to germinate. The grain is then soaked to absorb water

- The process begins with selecting high-quality malting barley, which is carefully cleaned and soaked to encourage germination. During the germination process, enzymes are activated that convert starch into sugar, which is crucial for fermentation.

- Once the barley has sprouted, it is kilned by drying it in an oven. This process stops the germination process and gives the malt its characteristic color and aromas. The temperature and duration of kilning have a significant influence on the taste of the malt and thus also of the subsequent beer.

- After kilning, the malt is carefully cleaned and sorted to ensure only the best grains are used. The finished malt is then shipped to breweries around the world, where it serves as the basis for beer production.

WATER:

WATER:  BARLEY:

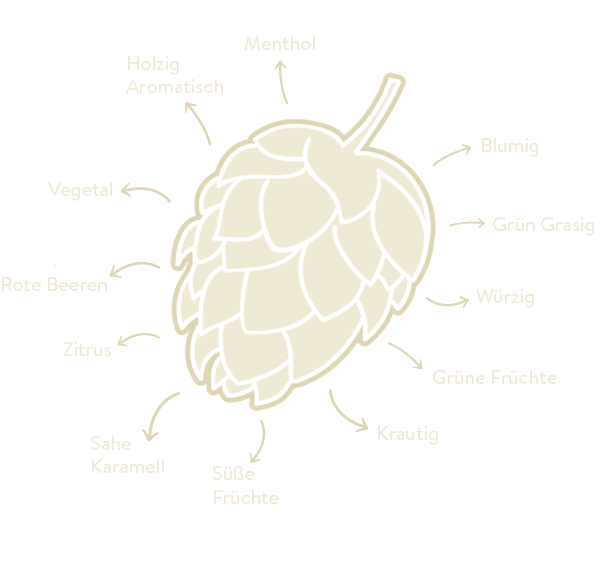

BARLEY: HOP:

HOP: